Ready To Serve You Well ...

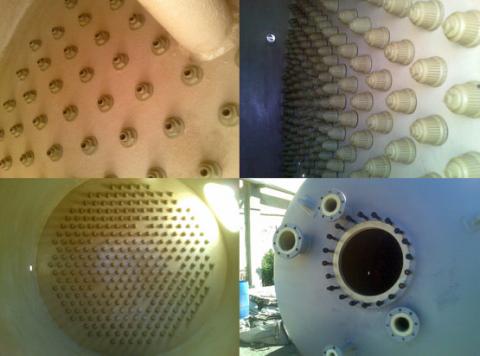

Refurbishment of Cation Exchanger Regeneration

Construction Date: January 2010

- Contracting Investor: Petrochemical industry, Egypt

Refurbishment and protection for petrochemical industry.

Scope of work

Complete refurbishment of process vessel currently out of service facing fatal corrosion problems. Previous hard rubber coating failed with lot of undercorroded areas.

Products

POLYGLASS Range

PLASMET ZF

Substrate

Carbon steel

Application Method

After taking down current hard ruber and 3 badly corroded parts rewelded, internal of the vessel protected against Sulphuric Acid 15% concentration attack at 60°C temperature, pressure 5 bars, using IFOS materials: primer PPA, Polyglass Pipe Grade for 296 vertical hole of nozzle plate (hot spot of job), Corrofill, Polyglass VEF, Polyglass Veil Coat. Postcured. External protected by Plasmet ZF.

Coating credentials

The success of this project has led to the customer specifying IFOS systems to protect other areas of petrochemical plant including high aggressive chemical and temperature attack areas.

Photographs

Previous hard rubber coating

Spray application of Polyglass VEF

Process vessel after refurbishment